NEWS

Understanding the Functionality and Benefits of Disc Pulverizers in Manufacturing

Oct 11,2025

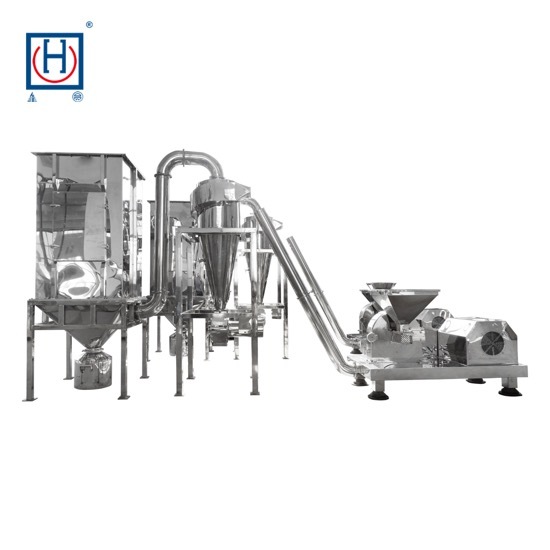

Disc pulverizers are critical components in the manufacturing and processing industries, particularly for crushing and sorting machinery. These machines are designed to efficiently reduce materials into fine powders or particles, making them invaluable in various applications ranging from plastics and chemicals to food processing and pharmaceuticals. Understanding the functionality and benefits of disc pulverizers can significantly improve operational efficiency and product quality in manufacturing processes.

At the core of a disc pulverizer’s operation is its unique design, which typically includes two parallel discs that rotate in opposite directions. This design allows materials to be fed into the pulverizer, where they are subjected to high levels of shear and impact forces. The result is a finely ground product that meets specific particle size requirements. The adjustable spacing between the discs enables operators to control the particle size, making disc pulverizers versatile tools suitable for a wide range of applications.

One of the main advantages of disc pulverizers is their ability to handle various materials effectively. Whether processing hard or brittle substances, disc pulverizers can adapt to the specific properties of the material, ensuring consistent results. This flexibility extends to different industries where the need for fine particle size is paramount, such as in the manufacturing of plastics, rubber, and even food products.

Moreover, disc pulverizers are designed for ease of maintenance and operational efficiency. Many modern models come equipped with features that facilitate quick access for cleaning and maintenance, which is crucial for minimizing downtime and maintaining production schedules. Additionally, their robust construction ensures durability and longevity, making them a worthwhile investment for manufacturers looking to enhance their processing capabilities.

Energy efficiency is another critical aspect of disc pulverizers. By optimizing the grinding process and reducing energy consumption, manufacturers can achieve significant cost savings. This is particularly important in today’s competitive landscape, where operational costs are closely monitored and controlled.

In conclusion, incorporating disc pulverizers into manufacturing operations can yield numerous benefits, including improved particle size control, versatility in material processing, ease of maintenance, and enhanced energy efficiency. As industries continue to seek innovative solutions for material processing challenges, disc pulverizers stand out as effective tools that can boost productivity and product quality. For manufacturers looking to optimize their processes, investing in a high-quality disc pulverizer is a strategic decision that can have lasting benefits.

At the core of a disc pulverizer’s operation is its unique design, which typically includes two parallel discs that rotate in opposite directions. This design allows materials to be fed into the pulverizer, where they are subjected to high levels of shear and impact forces. The result is a finely ground product that meets specific particle size requirements. The adjustable spacing between the discs enables operators to control the particle size, making disc pulverizers versatile tools suitable for a wide range of applications.

One of the main advantages of disc pulverizers is their ability to handle various materials effectively. Whether processing hard or brittle substances, disc pulverizers can adapt to the specific properties of the material, ensuring consistent results. This flexibility extends to different industries where the need for fine particle size is paramount, such as in the manufacturing of plastics, rubber, and even food products.

Moreover, disc pulverizers are designed for ease of maintenance and operational efficiency. Many modern models come equipped with features that facilitate quick access for cleaning and maintenance, which is crucial for minimizing downtime and maintaining production schedules. Additionally, their robust construction ensures durability and longevity, making them a worthwhile investment for manufacturers looking to enhance their processing capabilities.

Energy efficiency is another critical aspect of disc pulverizers. By optimizing the grinding process and reducing energy consumption, manufacturers can achieve significant cost savings. This is particularly important in today’s competitive landscape, where operational costs are closely monitored and controlled.

In conclusion, incorporating disc pulverizers into manufacturing operations can yield numerous benefits, including improved particle size control, versatility in material processing, ease of maintenance, and enhanced energy efficiency. As industries continue to seek innovative solutions for material processing challenges, disc pulverizers stand out as effective tools that can boost productivity and product quality. For manufacturers looking to optimize their processes, investing in a high-quality disc pulverizer is a strategic decision that can have lasting benefits.

More News