NEWS

Customizing Your Herb Pulverizer Machine for Unique Needs: A Comprehensive Guide

Oct 09,2025

Customizing Your Herb Pulverizer Machine for Unique Needs

Table of Contents

- Understanding Herb Pulverizer Machines

- Benefits of Customizing Your Herb Pulverizer

- Key Features to Customize in Your Pulverizer

- Materials and Design Considerations

- Motor and Power Options for Enhanced Performance

- Reducing Noise and Vibration in Your Machine

- Maintenance and Upkeep of Custom Herb Pulverizers

- Case Studies: Successful Customizations

- Frequently Asked Questions

- Conclusion

Understanding Herb Pulverizer Machines

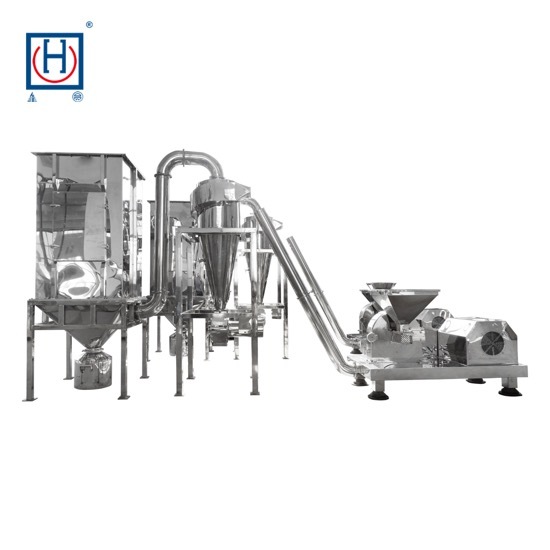

Herb pulverizer machines are essential in various industries, including pharmaceuticals, food processing, and herbal products. These machines efficiently grind herbs and other materials into fine powders, making them easier to use and integrate into various applications. Understanding the components and functionality of herb pulverizer machines is crucial before diving into customization.

A typical herb pulverizer consists of a feed hopper, grinding chamber, and discharge outlet. The machine operates using a motor that drives blades or hammers to crush and grind the material. The size of the output can vary based on the design and speed of the machine, making it essential for users to choose the right settings for their specific needs.

Benefits of Customizing Your Herb Pulverizer

Customizing your herb pulverizer machine can significantly improve its performance, efficiency, and adaptability. Here are some key benefits of tailoring your machinery to meet unique needs:

1. Enhanced Performance

Custom features can help optimize the grinding process, resulting in a finer and more consistent product. This is particularly important in industries where precision is crucial.

2. Increased Efficiency

By fine-tuning aspects of the machine, such as the speed and power settings, you can reduce processing time and increase overall throughput.

3. Reduced Wear and Tear

Custom materials and designs can lead to reduced friction and wear, extending the lifespan of your herb pulverizer and minimizing maintenance costs.

4. Improved User Experience

Custom ergonomic designs can enhance the comfort and usability of the machine, making it easier for operators to work efficiently.

Key Features to Customize in Your Pulverizer

When considering customization, various features of the herb pulverizer machine can be tailored to meet specific requirements.

1. Grinding Chamber Design

The shape and size of the grinding chamber can significantly affect the efficiency of the pulverization process. Customizing this component can help accommodate different types of herbs and materials, ensuring optimal performance.

2. Blade or Hammer Type

Choosing the right type of grinding mechanism—be it blades, hammers, or impact mills—can enhance the machine's effectiveness. Custom blade designs can improve the cutting and grinding efficiency for specific herbs.

3. Speed Settings

Adjusting the speed of the machine can allow for more control over the grinding process. Customizable speed settings can help users achieve the desired fineness or coarseness of their products.

4. Feed Rate

The rate at which materials are fed into the pulverizer can be customized to optimize the grinding process for different volumes and types of herbs, enhancing efficiency.

Materials and Design Considerations

The materials used in constructing your herb pulverizer are essential for its performance and durability. When customizing your machine, consider the following:

1. Material Composition

Choose high-quality materials resistant to corrosion, wear, and heat. Stainless steel is a popular choice due to its durability and ease of cleaning.

2. Machine Size and Footprint

Depending on your operational space, customizing the size and footprint of your herb pulverizer can help optimize work areas and improve overall efficiency.

3. Safety Features

Safety should always be a priority. Incorporating features such as emergency shut-off switches, safety guards, and overload protection can enhance the safety of the machine.

Motor and Power Options for Enhanced Performance

The motor is the heart of your herb pulverizer machine, influencing its overall efficiency and effectiveness. Customizing motor options can lead to significant performance improvements.

1. Motor Strength and Type

Selecting a motor with the appropriate horsepower and torque is critical. Consider options such as single-phase or three-phase motors based on your operational needs.

2. Energy Efficiency

Opt for energy-efficient motors that can reduce electricity costs and environmental impact while maintaining optimal performance.

3. Variable Speed Drives

Incorporating variable speed drives can allow for fine-tuning of the motor speed to match the specific requirements of different herbs.

Reducing Noise and Vibration in Your Machine

Excessive noise and vibration can not only be distracting but can also lead to mechanical issues over time. Customizing your herb pulverizer to minimize these factors can enhance your working environment.

1. Vibration Dampening Materials

Using materials designed to absorb vibrations can help reduce the overall noise level of the machine during operation.

2. Design Modifications

Implementing design changes, such as isolating the motor or using counterweights, can help reduce vibrations that lead to noise.

Maintenance and Upkeep of Custom Herb Pulverizers

Regular maintenance is essential to keep your herb pulverizer in optimal working condition. Customization can also lead to easier maintenance practices.

1. Accessible Components

Designing the machine with accessible components can make routine maintenance tasks, such as cleaning and part replacement, more manageable.

2. Lubrication Systems

Incorporating automated lubrication systems can reduce wear and tear on moving parts, ensuring smooth operation and longevity.

3. Routine Checks

Establish a regular maintenance schedule to inspect all parts of the machine for wear and damage, ensuring optimal performance at all times.

Case Studies: Successful Customizations

To illustrate the effectiveness of customizing herb pulverizer machines, consider these case studies:

1. Pharmaceutical Industry

A pharmaceutical company required a specific particle size for their herbal extracts. By customizing their herb pulverizer with adjustable speed and a specialized grinding chamber, they were able to achieve consistent results, significantly improving product quality.

2. Food Processing Sector

A food manufacturer faced challenges with ingredient consistency. By integrating a variable speed drive and customized blades, they enhanced their production line's efficiency, leading to increased production rates and reduced waste.

Frequently Asked Questions

1. What herbs can I pulverize using my customized machine?

You can pulverize a wide range of herbs, including dried leaves, roots, and spices. Customization allows the machine to handle specific herbs more efficiently.

2. How often should I maintain my herb pulverizer?

Regular maintenance is recommended, ideally every few weeks, depending on usage. Routine checks can help identify potential issues early.

3. Can I customize the size of my pulverizer?

Yes, many manufacturers offer customizable sizes and designs to fit your specific workspace and production needs.

4. What type of power source is best for a herb pulverizer?

The choice of power source depends on your production requirements. Single-phase motors are suitable for smaller operations, while three-phase motors are better for larger facilities.

5. How do I choose the right type of blade for my pulverizer?

The right blade type depends on the herbs you plan to process. Research the cutting mechanisms that work best with your specific materials to ensure optimal results.

Conclusion

Customizing your herb pulverizer machine can lead to significant improvements in performance, efficiency, and user experience. By understanding the key features to tailor, considering material choices, and implementing effective maintenance practices, you can ensure your pulverizer meets your unique needs. Whether you're in the pharmaceutical, food processing, or herbal products industry, customization opens the door to enhanced productivity and product quality. Explore the possibilities and unlock the full potential of your herb pulverizer today.

More News