NEWS

Understanding Fine Particle Pulverizers: Key Insights for the Manufacturing Industry

Sep 29,2025

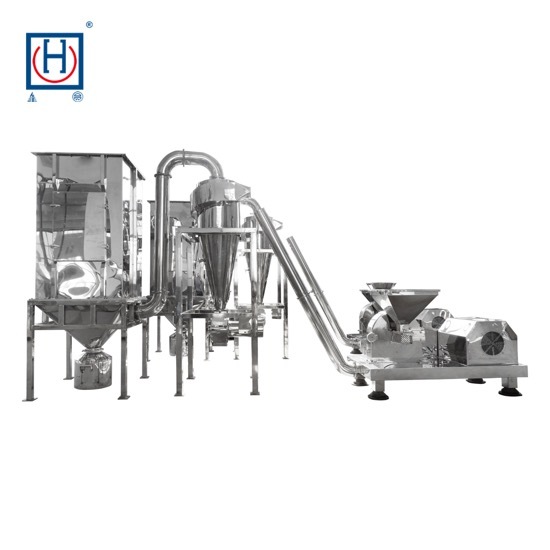

Fine particle pulverizers are specialized machines designed for the effective reduction of materials into fine powders. In the manufacturing and processing industries, the need for finely milled materials is paramount, as they are often required for various applications such as pharmaceuticals, food processing, and advanced materials development. This article delves into the workings, benefits, and applications of fine particle pulverizers, providing valuable insights for professionals in the industry.

At their core, fine particle pulverizers utilize mechanical force to crush and grind materials into particles of desired sizes. They employ a range of mechanisms, including impact, shear, and compression, to achieve uniform particle distribution. The choice of pulverizer often depends on the material being processed and the desired particle size. For instance, some materials may require a more aggressive grinding approach, while others may necessitate a delicate touch to prevent overheating or alteration of their properties.

One of the primary advantages of fine particle pulverizers is their ability to enhance material properties. By reducing particle size, the surface area of materials increases, which can significantly improve their reactivity and performance in various applications. This characteristic is particularly crucial in industries such as pharmaceuticals, where the bioavailability of a drug can be greatly affected by particle size. In addition, finer materials can lead to improved mixing and processing characteristics, which is vital for maintaining quality and efficiency in manufacturing processes.

Moreover, fine particle pulverizers contribute to waste reduction. By efficiently converting raw materials into usable forms, these machines minimize the amount of scrap and off-spec material produced during manufacturing. This efficiency not only conserves resources but also reduces the environmental impact of production processes, aligning with the growing emphasis on sustainable manufacturing practices.

In terms of maintenance, fine particle pulverizers require regular servicing to ensure optimal performance. Factors such as wear and tear on grinding elements, alignment issues, and motor performance are critical to address. A well-maintained pulverizer not only extends the machine's lifespan but also ensures consistent product quality and minimizes downtime.

As industries continue to innovate and evolve, the role of fine particle pulverizers will remain pivotal. Their capability to process a wide variety of materials into fine powders makes them indispensable in many manufacturing sectors. Professionals in the field should stay informed about advancements in pulverization technology and best practices to maximize the efficiency and effectiveness of these vital machines.

In conclusion, understanding the functionality and benefits of fine particle pulverizers can significantly enhance operational efficiency and product quality within the manufacturing industry. By leveraging these insights, industry professionals can make informed decisions that drive productivity and innovation.

At their core, fine particle pulverizers utilize mechanical force to crush and grind materials into particles of desired sizes. They employ a range of mechanisms, including impact, shear, and compression, to achieve uniform particle distribution. The choice of pulverizer often depends on the material being processed and the desired particle size. For instance, some materials may require a more aggressive grinding approach, while others may necessitate a delicate touch to prevent overheating or alteration of their properties.

One of the primary advantages of fine particle pulverizers is their ability to enhance material properties. By reducing particle size, the surface area of materials increases, which can significantly improve their reactivity and performance in various applications. This characteristic is particularly crucial in industries such as pharmaceuticals, where the bioavailability of a drug can be greatly affected by particle size. In addition, finer materials can lead to improved mixing and processing characteristics, which is vital for maintaining quality and efficiency in manufacturing processes.

Moreover, fine particle pulverizers contribute to waste reduction. By efficiently converting raw materials into usable forms, these machines minimize the amount of scrap and off-spec material produced during manufacturing. This efficiency not only conserves resources but also reduces the environmental impact of production processes, aligning with the growing emphasis on sustainable manufacturing practices.

In terms of maintenance, fine particle pulverizers require regular servicing to ensure optimal performance. Factors such as wear and tear on grinding elements, alignment issues, and motor performance are critical to address. A well-maintained pulverizer not only extends the machine's lifespan but also ensures consistent product quality and minimizes downtime.

As industries continue to innovate and evolve, the role of fine particle pulverizers will remain pivotal. Their capability to process a wide variety of materials into fine powders makes them indispensable in many manufacturing sectors. Professionals in the field should stay informed about advancements in pulverization technology and best practices to maximize the efficiency and effectiveness of these vital machines.

In conclusion, understanding the functionality and benefits of fine particle pulverizers can significantly enhance operational efficiency and product quality within the manufacturing industry. By leveraging these insights, industry professionals can make informed decisions that drive productivity and innovation.

More News