PRODUCTS

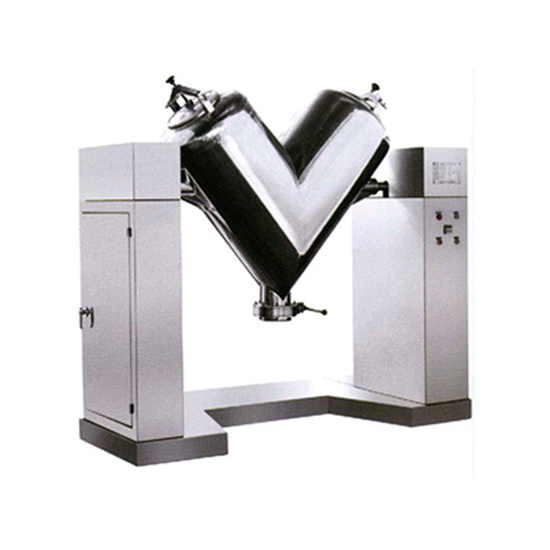

DTH single arm lifting hopper mixer series

Classification:

Product Introduction

PRODUCT MIX

Push the mixer hopper material into the swing arm and lock the nut to start the control system to lift the hopper to the mixing height. The control system of the quality hopper mixer products automatically mixes according to the set time, speed, and other data. At the end of the mixing operation, the fixed material is in the horizontal position, the hopper is automatically lowered to the ground, the whole machine stops, and the process data is printed. Loosen the lock nut of the swing arm and push the hopper out to the next process. Since the symmetrical axis of the hopper is at an angle to the rotary axis of the swing arm. The materials of different components move in three-dimensional space in a closed hopper, resulting in strong flipping and high shear to achieve a better mixing effect.

PERFORMANCE CHARACTERISTICS

1. High-tech products of electromechanical and hydraulic integration. Hydraulic lifting, hydraulic drive, PLC control; Easy control and easy adjustment of process parameters.

2. After each batch of drugs is mixed, the empty hopper is transported to a special cleaning room for cleaning to maintain a clean environment in the workshop.

3. The single machine can be equipped with a variety of specifications of hopper, and the mixed material is not discharged from the hopper from the swing arm with the hopper unloaded, directly transferred to the next process, which greatly improves the efficiency of the mixer, avoids cross-infection of materials, and meets the requirements of GMP.

4. The mixing hopper can be used as the batching barrel of the upper process and can be used as the hopper of the next process (tablet pressing, Han charging).

5. The mixing uniformity is above 99%, the volume whole material coefficient is 0.80, and the barrel is smooth inside and outside, without dead angles.

6. The control coefficient of the Best quality hopper mixer products is sensitive, the whole machine has a compact structure and stable and reliable operation.

TECHNICAL PARAMETERS

| Model Model | DTH-100 | DTH-200 | DTH-300 | DTH-400 | DTH-600 |

| Largest hopper volume (L) Maximum Hopper Volume | 100 | 200 | 300 | 400 | 600 |

| Largest loading volume (L) Max loading volume | 80 | 160 | 240 | 320 | 480 |

| Largest loading weight (kg) Max Loading Weight | 50 | 100 | 150 | 200 | 300 |

| Spindle speed (r/min) Spindle speed | 3-20 | 3-20 | 3-20 | 3-15 | 3-15 |

| Motor Power (kW) Motor Power | 4.5 | 3 | 3 | 4 | 4 |

| Total weight (kg). | 600 | 800 | 1000 | 1200 | 1400 |

| Overall Dimension(L*W*H) (mm) (L*W*H) | 2300*1500*1500 | 2500*1800*2000 | 2500*1900*2100 | 2600*2100*2300 | 2800*2300*2500 |

Key word:

Crusher / Mixer / Sifter / Granulator / Dryer / Feeding System

Related Products