PRODUCTS

GHJ-W type high efficiency mixer series

Classification:

Product Introduction

OVERVIEW OF OVERVIEW

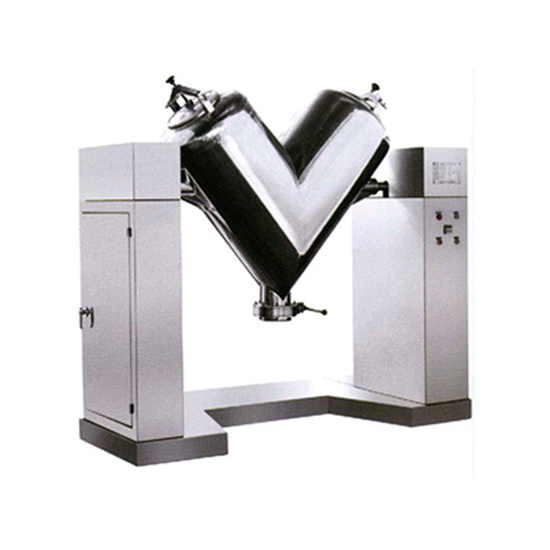

The function of this quality trough mixer machine in china is similar to that of a V-type mixer. Suitable for pharmaceutical, chemical, food, feed, dyes, electronics and other industries. This machine mixes powders and granules with good fluidity, and the effect is obvious. All technical indicators can meet the standards of similar foreign products. Simplified body made of stainless steel material, polished inside and outside, beautiful appearance, easy to operate.

This mixer has several advantages that make it popular in the industrial mixing field. First of all, its unique design, the tank-shaped container allows the mixture to be fully stirred, ensuring that the materials are evenly mixed throughout the mixing process. Secondly, it is suitable for a variety of materials, including powders, granules, and viscous substances, and has strong versatility.

In addition, the trough mixer in china has a remarkable mixing effect and can quickly complete the mixing process and improve production efficiency. Since the mixing process is carried out in a closed container, it can effectively reduce dust flying and ensure a clean working environment. It is also often equipped with advanced automated control systems to meet different production needs.

TECHNICAL PARAMETERS

| Model Model | W-30 | W-100 | W-300 | W-500 | W-1000 | W-1500 | W-2500 | W-4000 | W-6000 | W-8000 |

| Production capacity (L/batch) Throughput | 21 | 70 | 210 | 350 | 700 | 1050 | 1750 | 2800 | 4200 | 5600 |

| Mixing Time | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 |

| Full Volume (m³) Full Volume | 0.03 | 0.1 | 0.3 | 0.5 | 1 | 1.5 | 2.5 | 4 | 6 | 8 |

| Cylinder speed (rpm). | 0-15 | 0-15 | 0-15 | 0-15 | 0-12 | 0-12 | 0-12 | 0-10 | 0-10 | 0-10 |

| Motor Power (kW) Motor Power | 0.75 | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 22 |

| Weight (kg) Weight | 100 | 200 | 310 | 550 | 800 | 950 | 1650 | 1880 | 2350 | 2680 |

Key word:

Crusher / Mixer / Sifter / Granulator / Dryer / Feeding System

Related Products